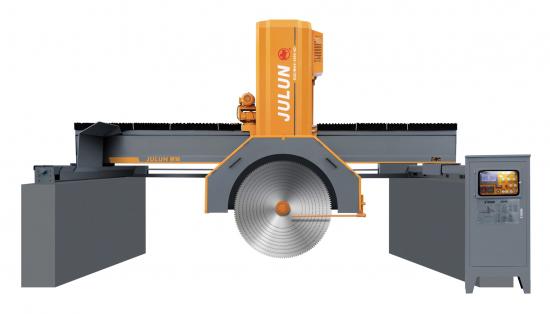

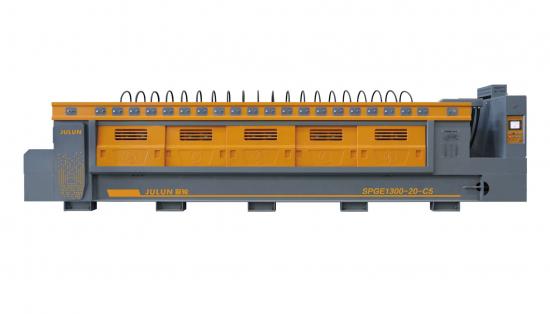

Combined Block Cutting Machine Guide Pillar Type

1.Stone processing machine uses PLC system and Human-machine Interface, combined with Ultra-high precision rotary encoder to slice, uses inverter to control left-right feeding, adjusts speed according to the stone material.

2.It uses hydraulic lifting system, combination of Chrome-plated guide pin and wear guide bush,with small gap,wearable, beautiful structure, and Guide Sleeve with multi-layer seals, with waterproof,dustproof, anti-spill,improving the service life. Forward-backward slicing uses high-precision screw nut driving, automatic slicing, main spare parts adopt imported good-quality materials; the block can be placed on the ground directly to economize the worktable and its maintenance costs;

3.Thus the big block cutting machine is featured with high cutting efficiency, high slicing precision, flatness of plate after cutting, high stability, easy-operating to suit granite and marble block with high value.

Note:360° rotating worktable can be selected if customer requires.

Specification

Appellation

unit

SQC/PC-2200/2500/2800-4D

Max.blade diameter

mm

Φ2200/Φ2500/Φ2800

Max.processing length

mm

3800/3500/3200

Max.processing width

mm

2200

Max.lifting stroke

mm

1150/1350/1350

Water consumption

m³/h

15

Power of main motor(optional)

kw

37/45

Total power

kw

47/55

Dimension(L×W×H) (from base to the highest point)

mm

8000×4400×3700

Weight

kg

12000

Guide pillar diameter

mm

φ140(can choose φ180 )

Photos

ipv6 network supported

ipv6 network supported